Overview

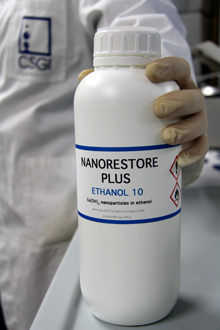

Calcium hydroxide nanoparticles dispersed in short-chain alcohols (also known as "nanolime")

are highly compatible with carbonate-based materials,

such as wall paintings and carbonatic stone. Due to their compatibility,

they represent an alternative to traditional consolidation materials used

in restoration practice, for instance synthetic polymer coatings that exhibit

poor compatibility with inorganic porous works of art and can produce detrimental

effects in the long-term.

When are they used?

Due to several reasons (pollution, weathering, mechanical stress) wall paintings and stones lose their original cohesion during time. When this happens a consolidation intervention has to be performed in order to recover the mechanical properties of the material and avoid the loss of the pictorial layer.

How do they work?

The particles penetrate into the pores and cracks of the artifacts, where they act as a binder

for the de-cohered layers and powdering surface of the works of art by turning into calcium carbonate through the reaction with atmospheric CO

2.

The carbonation process is highly favored by the nano-size of the particles.

How are they used?

The dispersions of nanoparticles are typically applied either by brushing (over Japanese paper)

or by spraying them over the artifact's surface. A humid cellulose poultice, or a light spray of

water, is then applied onto the treated surface to prevent the formation of white veils and to favor

the transformation of the hydroxide particles into carbonate. Full carbonation then takes place in 2-3 weeks,

also depending on the hydrothermal conditions. Several cycles of application can be carried out if need be to

provide consolidation of the weakened surface.

For further information, please refer to the technical sheet.

Reference textbooks

1. Piero Baglioni and David Chelazzi,

Nanoscience for the Conservation of Works of Art, Royal Society of Chemistry, 2013

2. Piero Baglioni, David Chelazzi and Rodorico Giorgi,

Nanotechnologies in the Conservation of Cultural Heritage: A Compendium of Materials and Techniques, Springer, 2014